Guide to Microclimate Management in Meat Curing

Microclimate Management in Meat Curing

Controlling the environment is crucial when curing meat. Moisture loss plays a pivotal role in preventing the growth of harmful bacteria and ensuring the safety of cured meats. The term “microclimate” encompasses the specific temperature and humidity conditions necessary for optimal meat curing. This guide will explore how effectively managing these conditions helps control microbial activity and enhance the flavours and textures of cured meats.

Understanding the Role of Water Activity in Meat Curing

Microorganisms require water to thrive. In meat curing, reducing the water activity — the measure of free water available for microbial processes — is essential. Minimising moisture makes the environment inhospitable to pathogens, which is crucial for preserving the meat’s safety over time. Achieving the right balance of moisture loss prevents microbes from growing, thus securing the meat from spoilage and extending its shelf life.

Optimizing Humidity for Effective Moisture Control

Managing the microclimate involves meticulous humidity control to balance moisture loss without causing case hardening. Case hardening occurs when the meat’s surface dries too rapidly, creating a barrier that traps internal moisture and leads to potential spoilage.

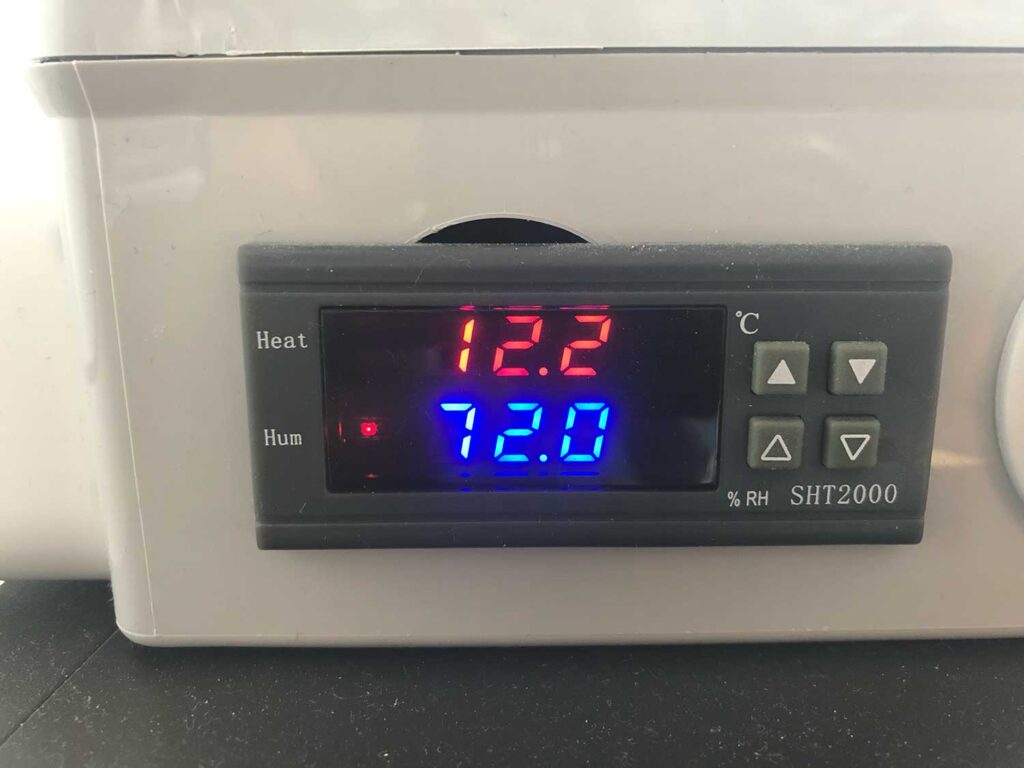

Keeping the relative humidity (RH) within an ideal range of 65% to 80%, with a target of 75% based on experience, supports gradual and uniform drying. This control is critical in achieving the desired texture and prolonging the product’s shelf life.

The Critical Impact of Temperature on the Curing Process

Temperature regulation is another vital aspect of the curing process. It significantly influences enzymatic reactions and microbial activity. Maintaining an optimal temperature range of 8°C/46.4°F to 14°C/57.2°F, ideally around 12°C/53.6°F, ensures that beneficial enzymatic reactions occur without accelerating spoilage. Proper temperature control contributes to developing rich flavours and safe meat curing outcomes.

Advanced and Traditional Methods to Manage the Microclimate

Controlled Maturing Chambers

Modern meat curing often employs controlled maturing chambers with advanced sensors and automation. These technologies allow for precise adjustments of humidity and temperature tailored to the curing stage and meat type, ensuring optimal conditions throughout the process.

Traditional Maturing Rooms

Artisanal meat curers might use traditional maturing rooms designed to naturally regulate temperature and humidity. These setups reflect a more classical approach to curing, relying on architectural features to maintain the microclimate.

Utilizing Humidifiers and Dehumidifiers

Humidifiers and dehumidifiers play essential roles in addressing varying humidity needs. Humidifiers add moisture to the air when necessary, especially in drier climates or seasons, while dehumidifiers remove excess humidity to curb mould growth and facilitate effective meat drying.

HVAC Systems in Meat Curing

HVAC systems are crucial for sustaining desired microclimates in more extensive or technologically sophisticated facilities. These systems provide consistent conditions year-round, which is crucial for maintaining quality despite external weather variations.

Monitoring and Adjusting the Curing Environment

Continuous monitoring with hygrometers, thermometers, and other sensors is vital for real-time tracking of the microclimate. These instruments provide data used to make necessary adjustments, ensuring the curing environment remains within ideal parameters.

Microclimate Management Accessibility for Home Curesmiths

While the complexity of microclimate management might seem daunting, it is often less complicated and expensive than anticipated. Most home curesmiths may not have access to advanced maturing environments, but it is possible to recreate effective microclimates within limited spaces and budgets. Understanding and implementing these principles can dramatically improve the safety and quality of home-cured meats.

Connect With Us

CURESMITH offers multiple platforms to engage with our community and access our resources:

- Website: www.curesmith.net – Your primary source for all our content and community interactions.

- YouTube: Subscribe to our weekly vlogs for a mix of education, information, and fun.

- Facebook Group: CURESMITH: Aged & Cured Meats Group – Membership-based group with over 39k members. CURESMITH manages one of the largest Facebook groups for Curesmiths. This is a true hivemind where likeminded Curesmiths share their experiences and recipes, as well as assist newbies into becoming proficient Curesmiths

- Social Media – Follow us to stay updated with the latest posts, discussions, and community activities on the following platforms: